ChipTest | BUs | Test Engineering

Project Feasibility Study

- Data Sheet & Product Functionality Review and Analysis

- Determination of Required Tests based on Product application and Electrical parameter specifications

- Tabulation of Test methodology for each test with input / output conditions & limits, in the form of a Test Plan Matrix

- Agreement with Customer on the derived Test Plan Matrix & Scope finalization

Hardware Design & Fabrication

- Selection of appropriate Tester platform capable of handling the product for the agreed Test Plan Matrix

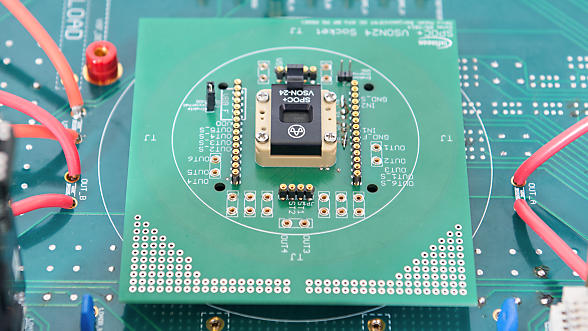

- Design of the product hardware load board schematic and the Adaptor Board for interfacing with the DUT

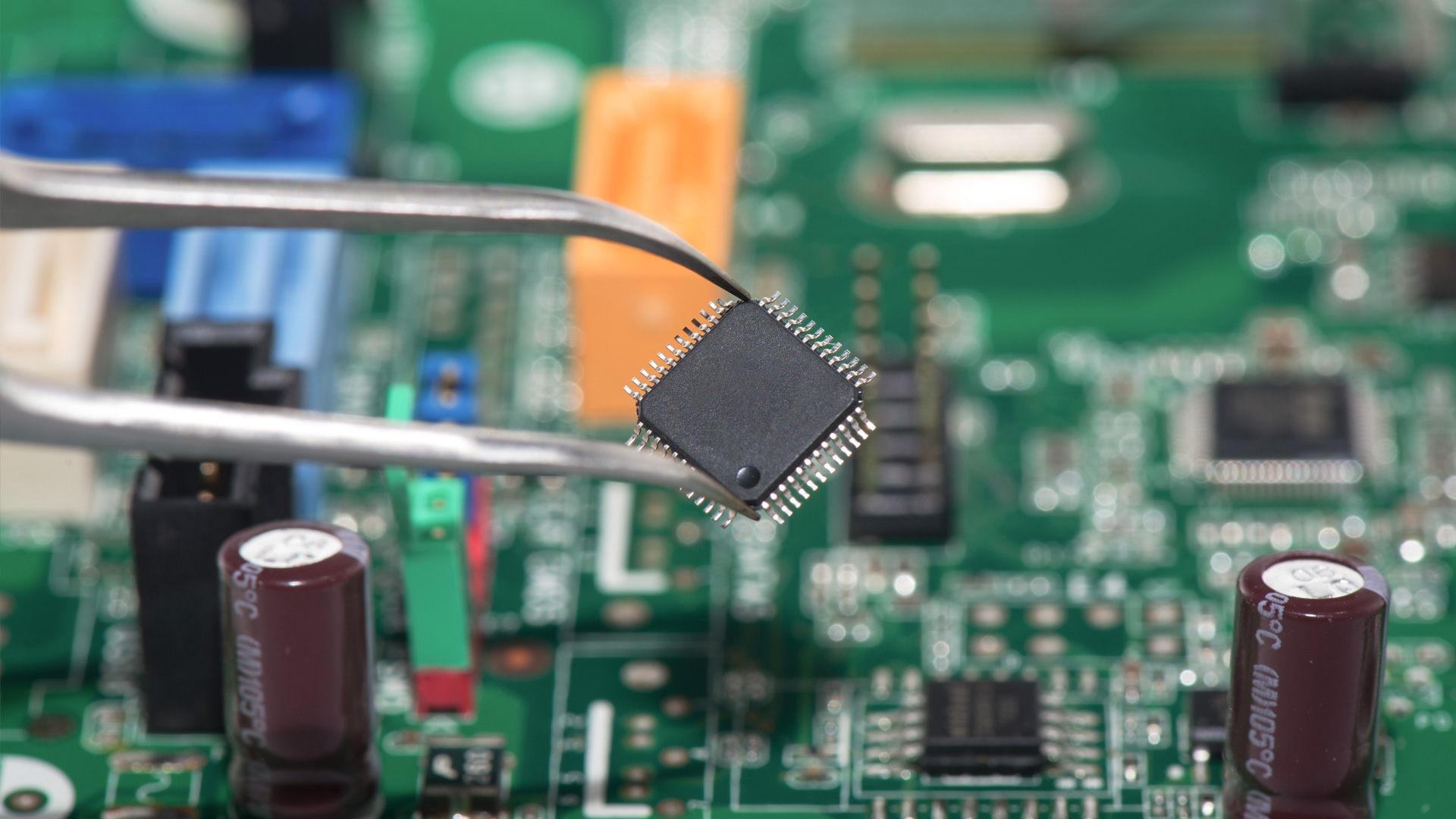

- Selection of Manual Test Socket, Handler Contactor Mechanism inclusive of the Mechanical interface design

- Design of the probe card based on the die pad layout and suitable interface with the Tester Load Board

- Fabrication of designed hardware modules like Load Board, Manual DUT Board, Handler Interface Board & the Probe Cards

Program Development & Debugging

- Development of the test program code for the designed hardware schematic as per the agreed Test Plan Matrix conditions

- Debugging of the program using the constructed hardware modules and known good products

- Verification of test measurement data for each parameter

- Refinement of hardware or test program depending upon the product characteristics & the observed values, for better performance

- Test Time Optimization is considered as part of the program debugging

Product Characterization & Correlation

- Verification & Refinement of the developed application program and set-up using Correlation Units provided by the Customer, wherever available

- Correlation of Tester measurements with Bench parameter values in case of

non-availability of known correlation units

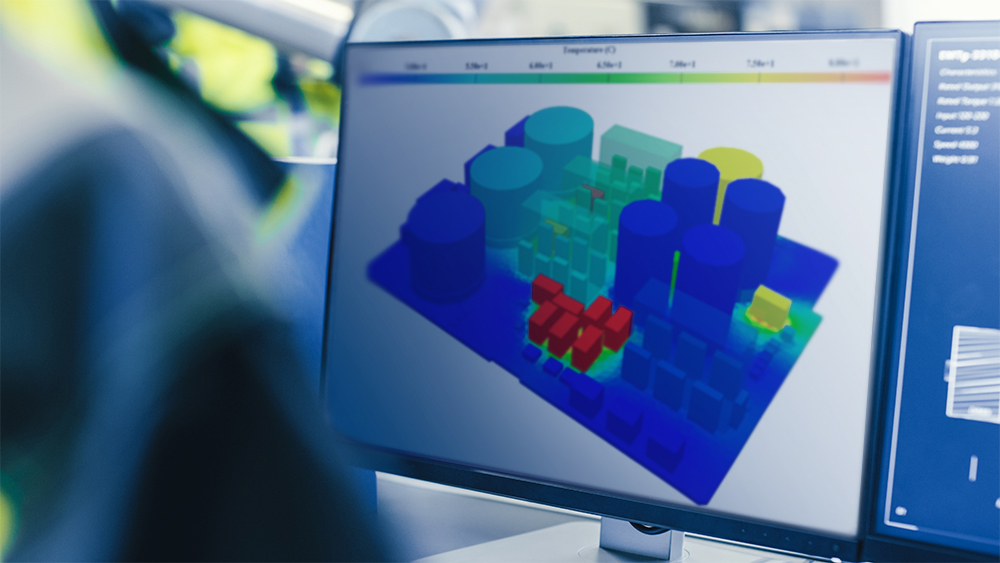

- Electrical Characterization of New products for various parameters & input conditions

- Statistical Analysis of the measured values & Determination of test limits

- Generation of Schmoo & Statistical distribution plots wherever possible for review by the Design team

General

- Bench level Characterization of new products and Data Analysis for Statistical distribution

- Onsite Test Engineering Support at Customer facility in their Test Equipments

- Proto type Samples packaging through associated working partners

- Lead Scan & Tape/Reel Finish process through associated working partners

- Capabilities exist for BarCode Labelling & Drop Shipment to End Users

Reliability

- Test Program Conversion from one platform to another & establish the correlation

- Bench level Characterization of new products and Data Analysis for Statistical distribution

- Onsite Test Engineering Support at Customer facility in their Test Equipments

- Proto type Samples packaging through associated working partners

- Lead Scan & Tape/Reel Finish process through associated working partners

- Capabilities exist for BarCode Labelling & Drop Shipment to End Users